FHV series are used for various purposes such as quenching, tempering and brazing of various metals. Vertical two-chamber configuration which consists of heating chamber + preparation/cooling contributes to space saving by adopting elevation mechanism. Temperature data from heating process to cooling process can be seamlessly recorded for quality control of products.

FHV series are used for various purposes such as quenching, tempering and brazing of various metals. Vertical two-chamber configuration which consists of heating chamber + preparation/cooling contributes to space saving by adopting elevation mechanism. Temperature data from heating process to cooling process can be seamlessly recorded for quality control of products.

Features

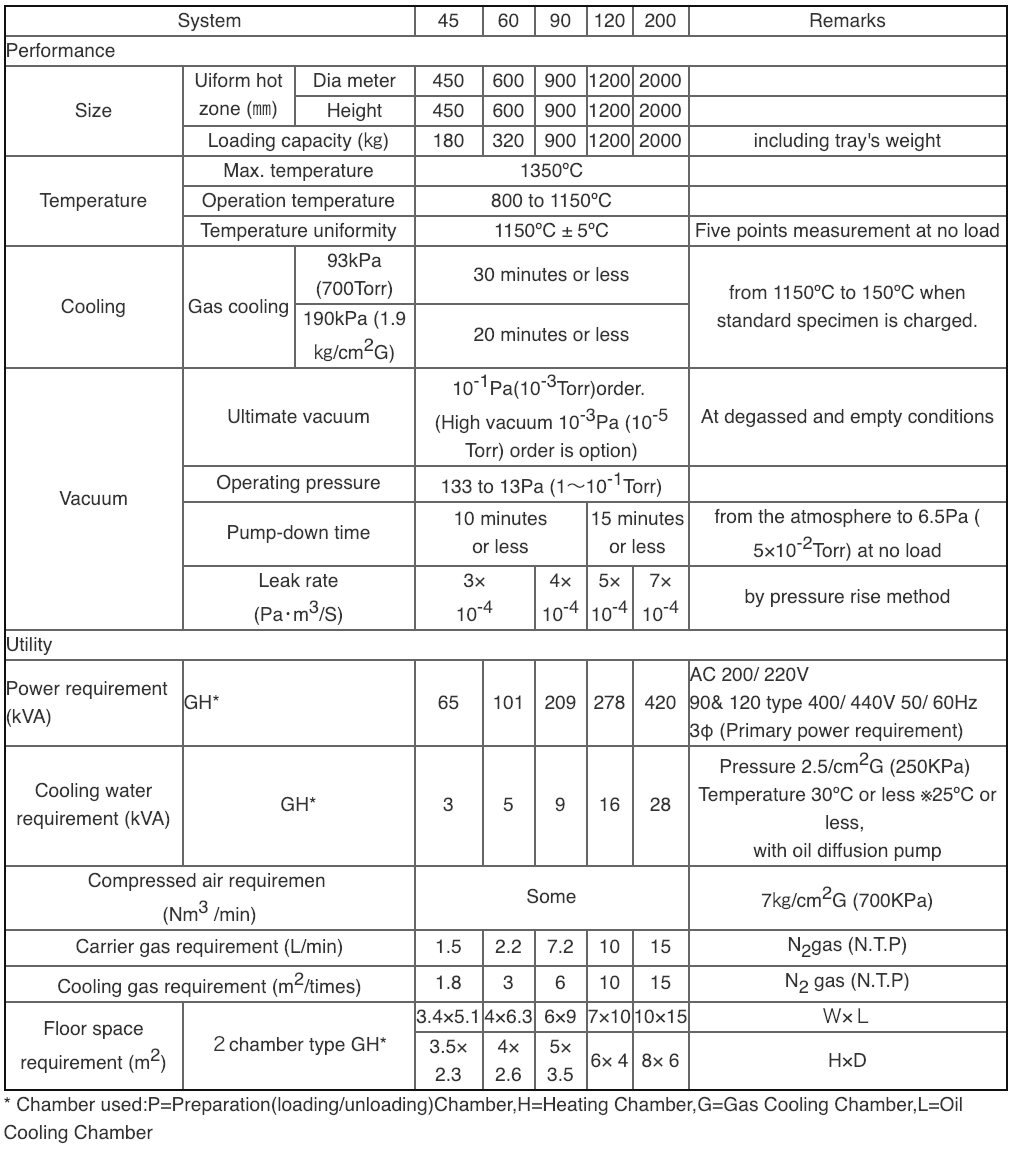

- Maximum temperature 1350ºC, Operation temperature 800 to 1150ºC

- Temperature uniformity is within ±5ºC at 1150ºC

- Keeping the heating chamber in vacuum for high quality and repeatability of products.

- Optional rotating cooling mechanism is suitable to process long products such as cutting tools.

- Thermocouple can be directly set on processing products for historical data of products temperature from heating to cooling as precise quality control.

Applications

- Quenching, Tempering : various machine parts, parts for air plane.

- Brazing : Heat exchanger, machine parts, parts for air plane, vacuum interception.

Specifications