Home » Vacuum Components » Vacuum Pump » Turbo Molecular Pump » Turbo Molecular Pump UTM-B Series

The compound turbo molecular pump with the ceramic ball bearings, and has excellent compression ratio. Compact design by integrated controller design. Excellent high back pressure performance allows to use smaller backing pump.

No limitation in the mounting direction The degree of freedom in system design is high because of free mounting direction.

Integrated controller is capable to reduce wire work and downsize pumping system.

High compression ratio made it possible to run the pump at high back pressure and downsize its backing pump.

Inlet port flange is selectable from ISO-K, ICF, and VG.

Less back flow of hydrocarbon gases while both the pump is running and stopping.

Noise level at the no load is 48dB or less(with ISO63-K flange)

| Model | UTM70B | UTM300B | |||||

| Pump | Cooing method | Natural air cooling |

Forced air cooling |

Natural air cooling |

Forced air cooling |

||

| Flange size | Inlet *1 |

VG65, ICF114, ISO063-K | VG100, ICF152, ISO100-K | ||||

| Outlet | KF16 | KF16 | |||||

| Pumping speed (without a protective net) |

N2 | 70 L/s | 280 L/s | ||||

| He | 60 L/s | 270 L/s | |||||

| H2 | 49 L/s | 220 L/s | |||||

| Ultimate pressure *2 |

After baking | – *3 | 10-8Pa | – *3 | 10-8Pa | ||

| Before baking | 10-6Pa | 10-6Pa | 10-6Pa | ||||

| Max. compression rate | N2 : >1×109, He : 4×107, H2 : 4×105 |

N2 : >1×109, He : 7×106, H2 : 1×105 |

|||||

| Max. pressure at inlet *4, *5, *6 |

N2 | 0.43Pa | 1.1Pa | 0.06Pa | 0.7Pa | ||

| Max. pressure at outlet *4, *5, *7 |

N2 | 300Pa | 900Pa | 100Pa | 1000Pa | ||

| Continuous running maximum flow *8 |

Without gas purge |

N2 | 15sccm *9 | 40sccm *9 | 10sccm *10 | 100sccm *10 | |

| Without gas purge |

Ar | – | 10sccm *9 | – | 30sccm *10 | ||

| With gas purge |

– | 15sccm *9 | – | 40sccm *10 | |||

| Recommend backing pump (when evacuating 10SCCM) *11 |

>60L/min | >120L/min | |||||

| Weight | VG:3.3kg, ISF:3.0kg, ISO:5.0kg | 6.0kg / 9.0kg | 6.3kg / 9.3kg | ||||

| Rotation speed | 87000rpm | 60000rpm | |||||

| Start-up time(Up to 80%) (DC24V. Back pressure:5Pa or less) |

1.7 min | 3.5 min | |||||

| Surface treatment *12 | None | ||||||

| Mounting direction | Free direction | ||||||

| Noise *13 | <48dB(A) | <50dB(A) | |||||

| Controller | Input power source | DC24V ±5%, 120W | DC24V ±5%, 180W | ||||

| Contact input and output signal |

REMOTE(D-sub 15 pin male) Digital input:4 points.Output:4 points.Analog output:1 point. |

||||||

| Serial communication | RS-485(D-sub 15 pin male, shared with REMOTE) | ||||||

| LED Display | POWER,NORMAL,ALARM | ||||||

| Switch | START/STOP,RESET | ||||||

| Variable rotational frequency/ speed | Change of operation rotation speed number is possible between 25% and 100% from the pump spec by 0.1% step. |

||||||

| Abnormal operation detection |

Detecting alarm and warning. | ||||||

| Protection circuit | Indicating alarm and warning. | ||||||

| Standard accessories | Instruction Manual(CD-R), Protective net(Only VG and ICF, ISO flange protective net is built in the gasket.), Gasket(inlet flange), Dust cap(for inlet, outlet and connector) |

||||||

| Applicable standard | CE, TUVus | ||||||

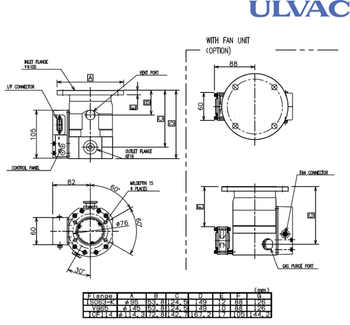

UTM-70B

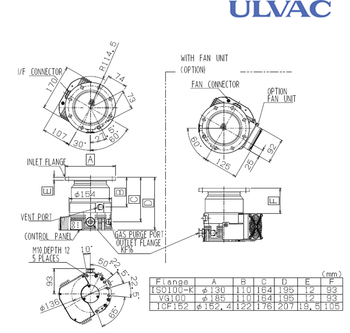

UTM-300B

Address: 110/6 Moo.13 Soi 25/2

Kingkaew Rd.,Rachathewa,

Bangplee,Samutprakan 10540

TEL: +66 2 738 8883

FAX: +66 2 738 8200