Home » Vacuum Components » Vacuum Pump » Turbo Molecular Pump » Turbo Molecular Pump UTM-MI Series

Controller integrated turbo molecular pump with magnetic bearings saves wiring work and installation space.

No wiring work between pump body and controller.

Free mounting direction makes the system design flexible.

Enabling the pressure adjustment in a chamber by changing the rotation speed.

Safety confirmation tests are passed, such as air rushing-in test and touch down test.

- Semiconductor equipmen

- Evaporator,Sputtering syste

- Analytical equipment,Experimental device and etc.

| Model | UTM1200A | UTM1600A | UTM2300A | UTM3400A | ||||||||

| Inlet port | VG 150 |

ISO 160F |

VG 200 |

VG 250 |

ISO 200F |

ISO 250F |

VG 250 |

ISO 250F |

VG 300 |

VG 350 |

ISO 320F |

|

| Outlet port | KF40 | |||||||||||

| Ultimate pressure *1 |

10-7 Pa | |||||||||||

| Pumping speed *2*3 |

N2 | 1030 L/s | 1400 L/s | 2100 L/s | 3200 L/s | |||||||

| Ar | 980 L/s | 1330 L/s | 2000 L/s | 3100 L/s | ||||||||

| H2 | 660 L/s | 750 L/s | 1380 L/s | 2100 L/s | ||||||||

| Comp ression rate |

N2 | 2×108 | ≧ 1×108 | ≧ 1×109 | ||||||||

| He | 7×103 | 5×103 | 1×105 | |||||||||

| H2 | 8×102 | 9×102 | 6×103 | |||||||||

| Max inlet pressure *4 |

26 Pa | 4.5 Pa | 7 Pa | |||||||||

| Max outlet pressure *4 |

266 Pa | 200 Pa | 270 Pa | |||||||||

| Rotation speed | 37200 min-1 | 33700 min-1 | 27600 min-1 | |||||||||

| Speed variation | Speed is variable between 25% and 100% of the rated speed.( set as 0.1%) | |||||||||||

| Start-up time | ≦ 8minutes | ≦ 9minutes | ≦ 16minutes | |||||||||

| Mounting position |

In any desired direction | |||||||||||

| Surface treatment *5 |

None | |||||||||||

| Commun ication |

Contact | D-sub 25 pin female Contact input and output signal | D-sub 37 pin female Contact input and output signal | |||||||||

| Serial | Serial connecter RS232C/RS485 | D-sub 9 pin male RS232C/RS485 | ||||||||||

| Controller | Compo sition |

Pump with integrated controller | ||||||||||

| Input electric power |

Single phase AC200 〜240V ±10%( 50/60Hz ±2Hz) | |||||||||||

| Max power |

0.75kVA | 1.2kVA | ||||||||||

| Cooling method | Water cooled | |||||||||||

| Cooling water *6 |

Flow rate |

3~4 L/min | ||||||||||

| Pressure | 0.2 ~ 0.4M PaG | |||||||||||

| Noise | 57 dB(A) | 60 dB(A) | ||||||||||

| Weight | 43 kg | 41 kg | 56 kg | 94 kg | ||||||||

| Recommended backing pump *7 |

≧ 600L/min | ≧ 1500L/min | ||||||||||

| Applicable standard | CE、TUVus | |||||||||||

| Standard accessories | O-ring(Only VG)、Dust cap(Outlet port)、Remote-control Connector、Instruction manual(CD-ROM) | |||||||||||

| Select parts |

AC Cable | AC Conector / AC Cable(5m/10m/15m/20m) | ||||||||||

| Special bolt for fixing pump |

M10/ M12 | |||||||||||

| Special bolt for fixing pump |

Need(M10) *8 | Not Need *8 | ||||||||||

| Option | Gas purge adaptor (KF10) | |||||||||||

*1 digit number is expressed.

*2 Without a protective net.

*3 Calculated values : UTM2300A and UTM3400A

*4 Max inlet pressure and Max outlet pressure cannot be satisfied at same time.

*5 Do not flow reactive gas and corrosive gas. Please contact us when using other gases.

*6 Not condensing

*7 When evacuating 30SCCM

*8 Grade of bolts,Fixing method and etc. are subject to various conditions. Please contact

us for the detailed information.

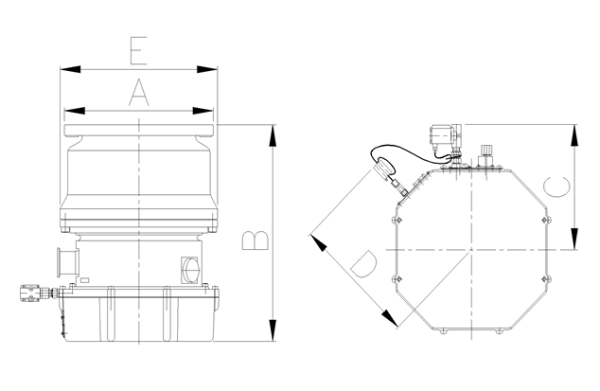

(mm)

| A | B | C | D | E | ||

| UTM1200A | VG150 | 235 | 439 | 218 | – | 285 |

| ISO160F | 225 | 442 | 218 | – | 285 | |

| UTM1600A | VG200 | 300 | 374 | 218 | – | 285 |

| ISO200F | 285 | 374 | 218 | – | 285 | |

| VG250 | 350 | 374 | 218 | – | 285 | |

| ISO250F | 335 | 374 | 218 | – | 285 | |

| UTM2300A | VG250 | 350 | 376 | 233 | 245 | 310 |

| ISO250F | 335 | 376 | 233 | 245 | 310 | |

| UTM3400A | VG300 | 400 | 462 | 233 | 245 | 360 |

| VG350 | 450 | 462 | 233 | 245 | 360 | |

| ISO320F | 425 | 467 | 233 | 245 | 360 | |

Note)The position and phase of outlet, gas purge port,

cooling water valve and cooling water valve connector are different to types.

Please contact us for the details information.

Address: 110/6 Moo.13 Soi 25/2

Kingkaew Rd.,Rachathewa,

Bangplee,Samutprakan 10540

TEL: +66 2 738 8883

FAX: +66 2 738 8200